Add to Cart

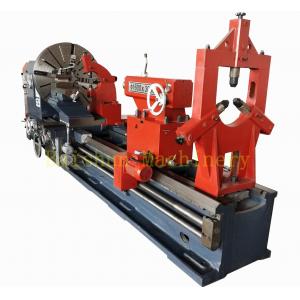

CW61160 good quality Universal metal Large Heavy Duty Lathe Machine Price

Product Application

The horizontal lathe machine is mainly suitable for cutting the workpiece inside and outside round cylindrical, cone and other rotating parts, machinable various commonly used metric, inch, module and diametral pitch thread, and broaching oil groove and keyway.The machine has the following features:

1. Horizontal Lathe Machine bed by integrally cast lathe bed structure, internal steel board layout is reasonable, has high rigidity, machine adopts the 250 casting iron, equipment with high frequency quenching, guide rail mill grinding process, stable machine tools with high precision, high rigidity, strong cutting.

2. Sliding box has a fast moving structure, single handle visualization operation;Spindle and reversing shift to the brake and the user can choose the hydraulic control or manual control machinery.

3. Horizontal Lathe Machine tool rest with single motor turning cylinder, you can also use the tool rest and longitudinal feed turning cone length.The machine it is suitable for large and medium-sized of steel and non-ferrous metal parts processing, can be cylindrical turning, inner hole, face cutting, drilling, boring and nesting.

4. The machine tool power, strong rigidity, spindle speed range is wide, suitable for strong or high speed cutting.Of spindle brake and shift to the hydraulic control, sensitive and reliable braking available button without a stop conversion speed, the forced lubrication with pressure oil in the cabinet of the head of a bed, spindle speed range has several kinds, for user to choose from.

Design feature:

1. The combination of flat bed creates a structure of extremely high accuracy and rigidity.

2. Our flat bed CNC lathe is equipped with turrets of either Chinese or western origin, with high

rigidity and accuracy, and fast indexing speed.

3. Spindle utilizes double-row cylindrical roller bearings for high accuracy and rigidity.

4. Hydraulic tailstock is an available option.

Heavy Duty Lathe Machine CW61160 Specification:

Manual Lathe Machine CW61160

| Item | Unit | CW61160 |

| Max swing over bed | mm | 1600 |

| Max. swing over carriage | mm | 1200 |

| Max workpiece length | mm | 3000/5000/6000-15000 |

| Bed width | mm | 1100 |

| Weight capacity | kg | 8000 |

| Hole through spindle | mm | 130 |

| Spindle taper |

| Metric 140 |

| Spindle speed Forward /Reverse |

| 21/12 |

| Spindle feed per rotation range |

| 56kinds |

| Portrait /Landscape | mm | 0.1-12/0.05-6 |

| Upper tool holder | mm | 0.25-3 |

| Metric threads range | mm | 44kinds 1-120 |

| Inch threads range | inch | 31kinds 24-1tpi |

| Moudle threads range | mπ | 45kinds 0.5-60 |

| Thread section number range | DP | 38kinds 1/2-56DP |

| Maximum travel of the saddle | mm | 2800/4800/5800-14800 |

| Maximum lateral travel of the lower tool holder | mm | 960 |

| Maximum stroke of the middle tool holder | mm | 300 |

| Maximum stroke of the upper tool holder | mm | 200 |

| Rapid movement speed of the tool holder Portrait /Landscape | mm/min | 3740/1870 |

| Middle tool holder | mm/min | 935 |

| Tailstock sleeve diameter | mm | 180 |

| Taper of tailstock sleeve |

| Metric 80 |

| Max.travel of tailstock | mm | 300 |

| Main motor power | kw | 22 |

| Machine size | mm | 7000x2320x2600 9000x2320x2600 10000-19000x2320x2600 |

| Net weight | kg | 21500/23600/24500-36300 |

Standard Accessories:

Centers

Steady rest

Follow rest

4-jaw chuck

Cooling system

Lubricant system

Work Lamp

Tool Box

Foundation bolts

Leveling iron pads

Chuck wrench

Our Services

1. We will provide all the machines for the complete production according to customer's requirements.

2. We will provide complete service for factory layout and other information to help buyer.

3. We will provide good service for the machine installation and training, until the customers can operate the machine and make stable production.

4. Except one year quality guarantee, we will provide after-selling service for all the life.

5. For long-term cooperation, we always provide good quality, good price and good service to customer.